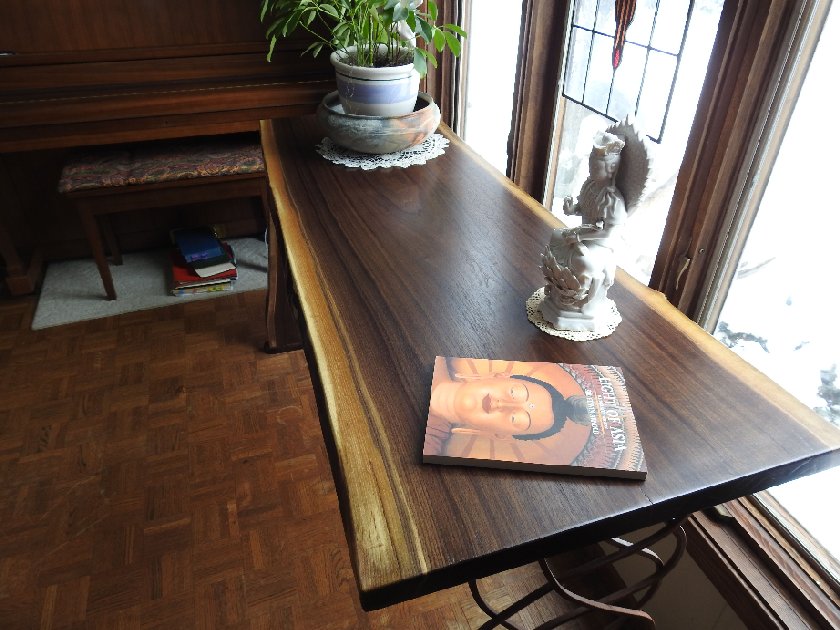

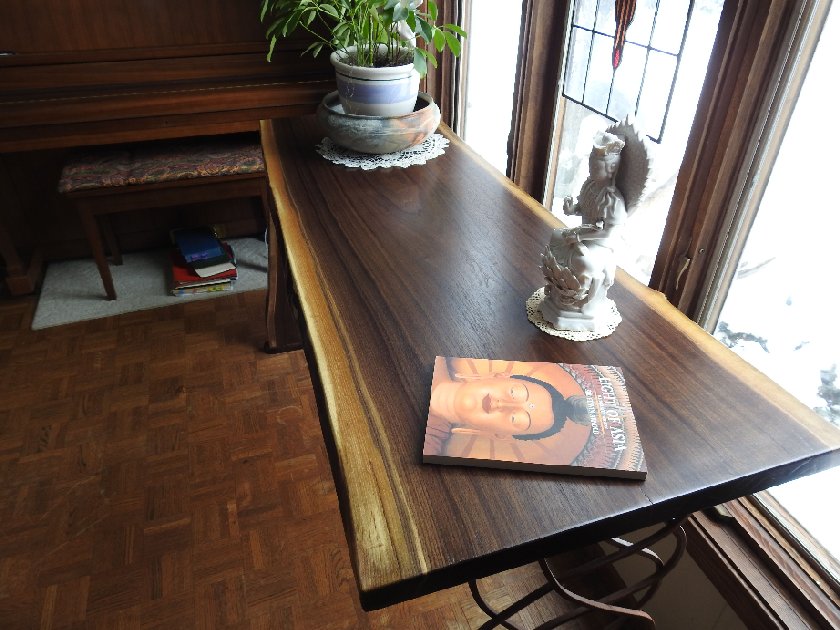

Custom Home Furnishings

The process starts with a discussion of what you are looking for. Type? Dimensions? Specie? Color? General design idea? Rustic? Finished? Using your wood vs our wood? We can help with design ideas at best show off the wood.

Schedule a day/time to come and see our inventory. Pick the wood slabs yourself if you would like or let us do it for you.

We love doing bookmatching and quarter sawing for our pieces. We have built dining tables in that manner many times; it is an economical but also beautiful solution. We work with walnut, oak, red elm, and ash very often. We usually build with solid, thick hardwood planks 2->3" thick and 15"->40+" wide.

Set the plan. Together we'll pull a project plan together. Time, Cost, Deliverables. We can do either the full project or any portion(s) on the project you wish.

Once your piece is ready, we'll schedule a pickup appointment. We also offer delivery in the Southern MN area.

This work is done using a variety of equipment such as a straightline rip, gangsaw, planer, molder, sander.

This work is done using a variety of equipment such as a straightline rip, gangsaw, planer, molder, sander.